燃气熔盐炉 燃气熔盐加热炉(Gas molten salt furnace Gas molten salt heating furnace)

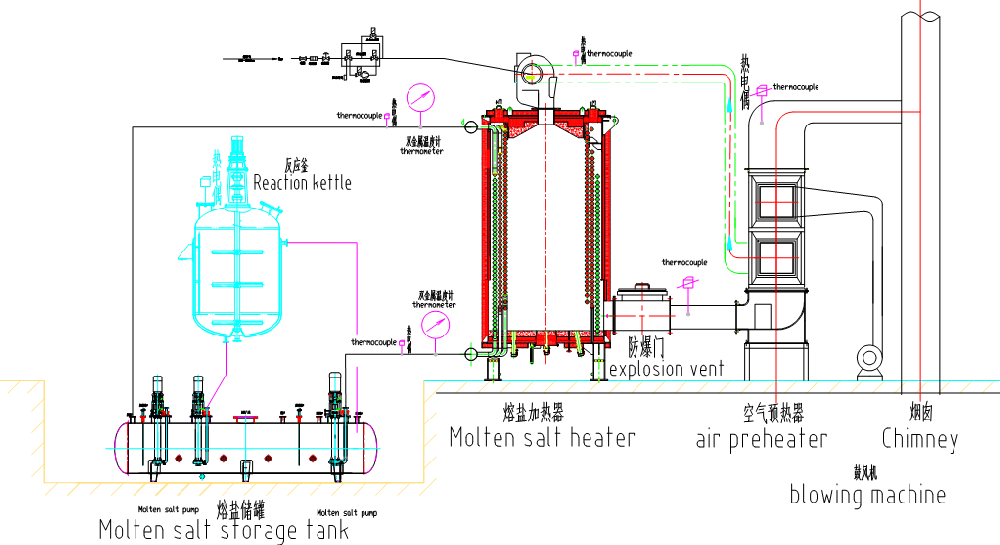

燃气熔盐炉是以天然气为燃料,以熔盐为热载体,利用熔盐泵强制液相循环,将热能输送给用热设备,继而返回重新加热的直流式特种工业炉。整个系统由熔盐供热系统、燃烧系统及控制系统构成:

Gas molten salt furnace is a special industrial furnace that uses natural gas as fuel and molten salt as a heat carrier. It uses a molten salt pump to force liquid-phase circulation, transfer heat energy to the heating equipment, and then return it to reheat. The entire system consists of a molten salt heating system, a combustion system, and a control system:

熔盐供热系统由熔盐炉本体、熔盐泵、熔盐槽及有关输送管线、阀门组成。

The molten salt heating system consists of the molten salt furnace body, molten salt pump, molten salt tank, and related conveying pipelines and valves

燃烧系统:主要由燃气供给系统、燃烧器、熔盐炉、烟道防爆门、空气预热器、烟气余热换热器、烟囱及有关阀门管线组成。

Combustion system: mainly composed of gas supply system, burner, molten salt furnace, flue explosion-proof door, air preheater, flue gas waste heat exchanger, chimney, and related valve pipelines.

控制系统分为动力控制和仪表显示控制两部分。

The control system is divided into two parts: power control and instrument display control.

动力控制主要控制熔盐罐内的电加热器,熔盐循环泵、风机、燃烧器等设备的起动与停止,同时循环泵与燃烧器之间进行联锁控制以保证加热炉的安全运行。Power control mainly controls the start and stop of the electric heater, molten salt circulation pump, fan, burner and other equipment in the molten salt tank. At the same time, interlocking control is carried out between the circulation pump and burner to ensure the safe operation of the heating

仪表显示控制:熔盐炉负荷是根据智能仪表出口油温的设置,通过仪表智能计算,进行 PID 调节功能, 自动调节 燃料量与空气供给量,以充分满足控制要求.

Instrument display control: The load of the molten salt furnace is set based on the outlet oil temperature of the intelligent instrument. Through intelligent calculation by the instrument, PID adjustment function is performed to automatically adjust the fuel and air supply to fully meet the control requirements

燃气熔盐炉广泛应用在固碱蒸发浓缩、三聚氰胺制取、氢氧化铝溶出、废液废油高温再生等化工单位;也可应用在太阳能光热发电的储能。

Gas molten salt furnaces are widely used in chemical units such as solid alkali evaporation concentration, melamine production, aluminum hydroxide leaching, and high-temperature regeneration of waste liquid and oil; It can also be used for energy storage in solar thermal power generation.

燃气熔盐炉出口应用于天燃气丰富的中东和西亚国家(如俄罗斯,乌磁别克斯坦,伊郎,伊拉克,沙特阿拉伯,土耳其,印度,巴基斯坦)各种需要进行高温加热的各行各业。

The export of gas-fired molten salt furnaces is used in various industries requiring high-temperature heating in Middle East and West Asia countries rich in natural gas (such as Russia, Ukraine, Iran, Iraq, Saudi Arabia, Türkiye, India, Pakistan).

燃气熔盐炉型号规格30-400万大卡参数表Model and Specification of Gas Molten Salt Furnace with a Capacity of 300000 to 4000000 kcal Parameters Table | |||||||||

型号 参数 | RYY(Q)-350 (30) | RYY(Q)-700 (60) | RYY(Q)-960 (80) | RYY(Q)-1200 (100) | RYY(Q)-1400 (125) | RYY(Q)-2400 (200) | RYY(Q)-3500 (300) | RYY(Q)-4600 (400) | |

额定热功率 kW Rated thermal power kW | 350 | 700 | 960 | 1200 | 1400 | 2400 | 3500 | 4600 | |

热效率 % Thermal efficiency% | 70 | 70 | 70 | 70 | 70 | 70 | 75 | 75 | |

设计压力 MPa Design pressure MPa

| 1 | 1 | 1 | 1.1 | 1.1 | 1.1 | 1.3 | 1.3 | |

最高介质温度 ℃ Maximum medium temperature ℃ | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | |

炉内介质容量 m3 Furnace medium capacity m3 | 0.35 | 0.5 | 0.7 | 0.95 | 1.7 | 3 | 4.9 | 5 | |

循环量m3 /h Circulation volume m3/h | 40 | 40 | 50 | 80 | 170 | 80 | 250 | 170 | |

配管联接口径 DN Pipe connection diameter DN | 100 | 100 | 125 | 125 | 150 | 150 | 250 | 200 | |

系统装机容量 kW | 30 | 30 | 30 | 50 | 55 | 60 | 130 | 130 | |

外 形 尺 寸 | 直径 mm Diameter mm | Φ1710 | Φ1710 | Φ1910 | Φ2020 | Φ2400 | Φ2970 | Φ3250 | Φ3400 |

高 mm Height mm | 2600 | 3300 | 3600 | 4100 | 4000 | 6400 | 7000 | 8000 | |

设备总重量 kg Total weight of equipment kg | 3900 | 4350 | 5290 | 6360 | 8600 | 18410 | 25000 | 31000 | |

| 燃气熔盐炉型号规格600-2000万大卡参数表 Model and Specification of Gas Molten Salt Furnace with a Capacity of 6000000 to 20000000 kcal Parameters Table | |||||||||

型号 参数 | RYY(Q)-7000 (600) | RYY(Q)-8170 (700) | RYY(Q)-10500 (900) | RYY(Q)-12000 (1000) | RYY(Q)-14000 (1200) | RYY(Q)-15122 (1300) | RYY(Q)-17445 (1500) | RYY(Q)-23260 (2000) | |

额定热功率 kW Rated thermal power kW | 7000 | 8170 | 10500 | 12000 | 14000 | 15122 | 17445 | 23260 | |

热效率 % Thermal efficiency% | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | |

设计压力 MPa Design pressure MPa

| 1.3 | 1.8 | 1.8 | 1.9 | 1.6 | 1.6 | 2.0 | 1.8 | |

最高介质温度 ℃ Maximum medium temperature ℃ | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | |

炉内介质容量 m3 Furnace medium capacity m3 | 9.1 | 10.9 | 13 | 13 | 15 | 18 | 21 | 25 | |

循环量m3 /h Circulation volume m3/h | 230 | 250 | 360 | 400 | 440 | 300 | 500 | 900 | |

配管联接口径 DN Pipe connection diameter DN | 200 | 250 | 300 | 300 | 300 | 250 | 350 | 400 | |

系统装机容量 kW | 160 | 240 | 280 | 300 | 350 | 350 | 400 | 700 | |

外 形 尺 寸

| 直径 mm Diameter mm | Φ3650 | Φ3700 | Φ3950 | Φ4080 | Φ4080 | Φ4450 | Φ4520 | Φ4800 |

高 mm Height mm | 10340 | 11360 | 12050 | 11840 | 14500 | 14000 | 16000 | 16600 | |

设备总重量 kg Total weight of equipment kg | 47200 | 51800 | 65440 | 70000 | 91550 | 98320 | 108180 | 122080 | |

注:热效率指炉体热效率,配置余热回收装置后,系统热效率可大于90%以上。

Note: Thermal efficiency refers to the thermal efficiency of the furnace body. After configuring a waste heat recovery device, the system's thermal efficiency can exceed 90% or more.

燃气熔盐炉特点:Characteristics of Gas Molten Salt Furnace:

1. 低压高温,安全性强,与导热油相比在相同的压力下可获得更高的使用温度;

1. Low pressure and high temperature, strong safety, and can achieve higher operating temperatures compared to heat transfer oil under the same pressure;

2. 供热温度稳定,能准确地进行负荷、温度调整;

2. Stable heating temperature, able to accurately adjust load and temperature;

3. 系统热效率高,普遍高于92%以上;

3. The thermal efficiency of the system is high, generally above 92%;

4. 运行控制和安全监测装备完备,有效降低运维成本;

4. Complete operation control and safety monitoring equipment, effectively reducing operation and maintenance costs;

5. 自动控制:机械化、全自动控制、比例调节、PLC可编程或DCS人机对话集成控制技术;

5. Automatic control: Mechanized, fully automatic control, proportional adjustment, PLC programmable or DCS human-machine dialogue integrated control technology;

6. 熔盐炉因供热负荷和循环流量不同,大多采用二层或三层圆盘管形式,内圈盘管为辐射受热面,中圈盘管、外圈盘管为对流受热面,三层盘管并联运行,结构简单,使用方便。

6. Due to different heating loads and circulating flow rates, molten salt furnaces mostly adopt the form of two-layer or three-layer circular tubes. The inner coil is a radiating heating surface, while the middle and outer coils are convective heating surfaces. The three-layer coils operate in parallel, with a simple structure and convenient use.

7. 燃气熔盐炉为立式,占地面积少,炉管内熔盐可以靠自重排空,燃烧器分布在炉体的顶部或者在底部,筒体主材: 12Cr1MoVR, 管材:12Cr2MoG。

7. The gas molten salt furnace is vertical and occupies a small area. The molten salt inside the furnace tube can be emptied by its own weight. The burners are distributed at the top or bottom of the furnace body. The main material of the cylinder is 12Cr1MoVR, and the pipe material is 12Cr2MoG.

| 中国常州市上能锅炉有限公司联系方式 Contact information of Changzhou Shangneng Boiler Co., Ltd., China 联系人:芮亚平 Contact person: Rui Yaping 手机:+8613815029577 Mobile:+8613815029577 微信号:13815029577 WeChat ID: 13815029577 邮箱:czjnguolu@163.com Email: czjnguolu@163.com 工厂地址:中国常州高新区黄河西路225号 Factory address: No. 225 Huanghe West Road, Changzhou High tech Zone, China 开户行:中国工商银行常州钟楼支行 Opening Bank: Industrial and Commercial Bank of China Changzhou Zhonglou Branch 美元帐号:1105020509714031781 USD account: 1105020509714031781 |