燃气导热油炉 燃气导热油锅炉(Gas thermal oil boiler)

燃气导热油炉,燃气导热油锅炉,出口应用于天燃气丰富的中东和西亚国家(如俄罗斯,乌磁别克斯坦,伊郎,伊拉克,沙特阿拉伯,土耳其,印度,巴基斯坦)各种需要进行高温加热的各行各业。

Gas fired heat transfer oil furnaces and gas fired heat transfer oil boilers are exported to various industries requiring high-temperature heating in Middle East and West Asia countries rich in natural gas (such as Russia, Uzbekistan, Iran, Iraq, Saudi Arabia, Türkiye, India, Pakistan).

燃气导热油炉,燃气导热油锅炉是以天燃气为燃料,导热油为热载体,通过循环泵强制液相循环,将热能输送给用热设备,换热后返回加热炉重新加热的直流式特种工业炉。

Gas thermal oil furnace and gas thermal oil boiler are special industrial furnaces that use natural gas as fuel, thermal oil as heat carrier, and forced liquid-phase circulation through circulation pumps to transfer heat energy to heating equipment. After heat exchange, they are returned to the heating furnace for reheating.

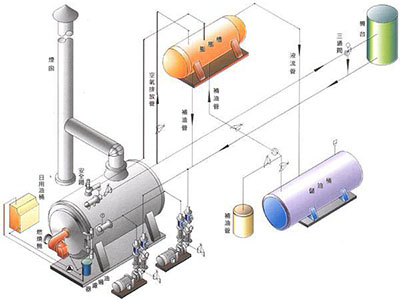

燃气导热油炉,燃气导热油锅炉主要由供热系统、燃烧系统及控制系统构成。

Gas thermal oil furnace and gas thermal oil boiler mainly consist of heating system, combustion system, and control system.

1.1供热系统:主要由循环油泵、加热炉本体、热用户(用热设备)、油气分离器及相关阀门管线构成,如储油槽、膨胀槽、注油泵等也都是不可缺少的辅助管路及设备。

1.1 Heating system: mainly composed of circulating oil pump, heating furnace body, heat user (heat equipment), oil and gas separator, and related valve pipelines, such as oil storage tank, expansion tank, oil injection pump, etc., are also indispensable auxiliary pipelines and equipment.

1.2燃烧系统:主要由燃气供给系统、燃烧器、加热炉、烟道防爆门、空预器、烟囱及有关阀门管线组成。

1.2 Combustion system: mainly composed of gas supply system, burner, heating furnace, flue explosion-proof door, air preheater, chimney, and related valve pipelines.

1.3控制系统:控制系统分为动力控制和仪表显示控制两部分。

1.3 Control System: The control system is divided into two parts: power control and instrument display control.

动力控制主要控制循环泵、注油泵、助燃空气风机、燃烧器等设备的起动与停止,同时循环泵与燃烧器之间进行联锁控制以保证加热炉进行安全运行。

Power control mainly controls the start and stop of equipment such as circulation pumps, oil injection pumps, combustion air fans, and burners. At the same time, interlocking control is carried out between the circulation pumps and burners to ensure the safe operation of the heating furnace.

仪表显示控制通常采用出口油温控制燃烧器进行油温调节、进出口油温显示、热载体压差报警、膨胀槽液位报警及最终排烟温度显示,采用温度信号控制燃烧器,使其达到自动控制功能。

Instrument display control usually uses outlet oil temperature control burner for oil temperature regulation, inlet and outlet oil temperature display, heat carrier pressure difference alarm, expansion tank liquid level alarm, and final exhaust gas temperature display. Temperature signal control burner is used to achieve automatic control function.

在自动控制系统的管理下,通过各系统的互相协调,可实现以下功能:

Under the management of the automatic control system, the following functions can be achieved through the coordination of various systems:

1) 为用热设备提供满足负荷要求的稳定高温热源;

1) Provide stable high-temperature heat sources that meet load requirements for thermal equipment;

2) 保持整个热系统稳定运行,实现不间断连续运行;

2) Maintain stable operation of the entire thermal system and achieve uninterrupted continuous operation;

3) 实现加热炉热负荷自动调节;

3) Realize automatic adjustment of heating furnace heat load;

4) 实现热载体炉在非正常工况下的安全连锁反馈保护;

4) Implement safety chain feedback protection for heat carrier furnaces under abnormal working conditions;

5) 具有各种非正常情况下的预警、报警、故障锁定等功能;

5) Has various functions such as early warning, alarm, and fault locking under abnormal conditions;

6) 实现循环油泵的切换,完成运行中的热油即时过滤;

6) Realize the switching of the circulating oil pump and complete the real-time filtration of hot oil during operation;

7) 可实现自动无人运行。

7) Can achieve automatic unmanned operation.

燃气导热油炉以它的低压高温、运行安全、控制先进、效益显著等特点得到了国内外各行业的极大关注,广泛应用于石油化工:油脂: 塑料橡胶: 皮革行业: 纺织印染: 化纤纤维: 涂装油漆: 汽车飞机: 木材加工: 林产工业: 造纸印刷: 建筑建材: 碳素工业:公路交通: 市政公路筑路: 沥青加热: 制药工业: 原子能工业:金属加工: 食品工业等工业领域,其发展至今,已成为国民经济中必不可少的节能型供热设备。

Gas thermal oil furnaces have attracted great attention from various industries both domestically and internationally due to their characteristics of low pressure and high temperature, safe operation, advanced control, and significant benefits. They are widely used in industries such as petrochemicals, fats, plastics, rubber, leather, textile printing and dyeing, chemical fibers, painting, automobiles and airplanes, wood processing, forestry industry, papermaking and printing, building materials, carbon industry, highway transportation, municipal road construction, asphalt heating, pharmaceutical industry, atomic energy industry, metal processing, and food industry. Since its development, it has become an essential energy-saving heating equipment in the national economy.

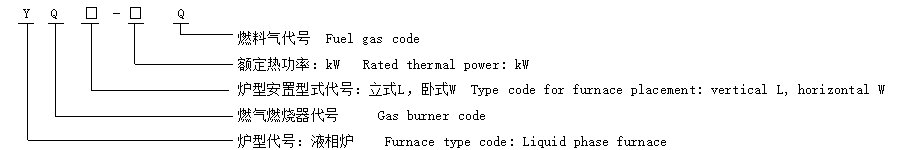

燃气导热油炉,燃气导热油锅炉规格型号有:立式与卧式之分

There are two types of specifications for gas thermal oil boilers: vertical and horizontal

型号规格编制规则 Rules for Model and Specification Compilation

示例:YQL-1200Q:液相循环立式燃气炉,热功率1200kW。Example: YQL-1200Q: Liquid phase circulation vertical gas furnace, thermal power 1200kW.

YQW(L) 15~250 ×104kcal/h燃气导热油锅炉型号规格参数YQW (L) 300~1200 × 104kcal/h Fuel Gas Thermal Oil Boiler Model Specification Parameters | ||||||||||

型号 参数 | YQW-180 (15) | YQW-350 (30) | YQW-600 (60) | YQW-850 (80) | YQW-1200 (100) | YQW-1400 (125) | YQW-1800 (150) | YQW-2400 (200) | YQW-3000 (250) | |

额定热功率 kW Rated thermal power kW | 180 | 350 | 700 | 940 | 1200 | 1400 | 1800 | 2400 | 3000 | |

热效率 % | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | |

设计压力 MPa Thermal efficiency% | 1 | 1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

最高介质温度 ℃ Maximum medium temperature ℃ | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | |

炉内容油量 m3 Oil content in the furnace, m3 | 0.16 | 0.32 | 0.4 | 0.77 | 1.2 | 1.35 | 1.48 | 2.6 | 3.2 | |

循环油量m3 /h Circulating oil volume m3/h | 20 | 40 | 60 | 80 | 100 | 100 | 100 | 200 | 200 | |

配管联接口径 DN Pipe connection diameter DN | 50 | 100 | 100 | 100 | 125 | 125 | 125 | 150 | 150 | |

系统装机容量 kW System installed capacity kW | 11 | 14 | 30 | 30 | 45 | 45 | 45 | 70 | 80 | |

外 形 尺 寸 | 长 mm Length mm | 1600 | 2600 | 3000 | 3150 | 3560 | 3830 | 4200 | 4700 | 5250 |

宽 mm Width mm | 1300 | 1420 | 1700 | 2100 | 2400 | 2550 | 2600 | 3000 | 3000 | |

高 mm Height mm | 1500 | 1730 | 1700 | 1860 | 2140 | 2200 | 2270 | 2600 | 2660 | |

设备总重量 kgT otal weight of equipment kg | 2565 | 3400 | 3670 | 4810 | 6500 | 7250 | 8250 | 12000 | 13800 | |

注:热效率指炉体热效率,配置余热回收装置后,系统热效率可达到92%以上

Note: Thermal efficiency refers to the thermal efficiency of the furnace body. After configuring a waste heat recovery device, the system's thermal efficiency can reach over 92%

YQW(L) 300~1200 ×104kcal/h燃油燃气导热油锅炉型号规格参数YQW (L) 300~1200 × 104kcal/h Fuel Gas Thermal Oil Boiler Model Specification Parameters | ||||||||||

型号 参数 | YQW-3500 (300) | YQW-4000 (350) | YQW-4600 (400) | YQW-6000 (500) | YQW-7000 (600) | YQW-8170 (700) | YQW-9500 (800) | YQW-12000 (1000) | YQW-14000 (1200) | |

额定热功率 kW Rated thermal power kW | 3500 | 4000 | 4600 | 6000 | 7000 | 8170 | 9500 | 12000 | 14000 | |

热效率 % | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | |

设计压力 MPa Thermal efficiency% | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

最高介质温度 ℃ Maximum medium temperature ℃ | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | |

炉内容油量 m3 Oil content in the furnace, m3 | 3.9 | 4.6 | 5.6 | 7.5 | 9 | 11 | 13 | 14 | 18.6 | |

循环油量m3 /h Circulating oil volume m3/h | 200 | 300 | 300 | 300 | 340 | 400~500 | 400~500 | 400~500 | 800 | |

配管联接口径 DN Pipe connection diameter DN | 150 | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 350 | |

系统装机容量 kW System installed capacity kW | 80 | 120 | 120 | 130 | 150 | 230 | 230 | 270 | 300 | |

外 形 尺 寸

| 长 mm Length mm | 5650 | 6100 | 6800 | 7500 | 8650 | 9200 | 10200 | 10800 | 12000 |

宽 mm Width mm | 3200 | 3350 | 3500 | 3900 | 4000 | 4100 | 4200 | 4500 | 4500 | |

高 mm Height mm | 2860 | 2990 | 3140 | 3500 | 3600 | 3730 | 3730 | 3980 | 4120 | |

设备总重量 kgT otal weight of equipment kg | 16070 | 17620 | 20450 | 25000 | 29850 | 33970 | 37000 | 42600 | 53000 | |

注:热效率指炉体热效率,配置余热回收装置后,系统热效率可达到92%以上

Note: Thermal efficiency refers to the thermal efficiency of the furnace body. After configuring a waste heat recovery device, the system's thermal efficiency can reach over 92%

| 中国常州市上能锅炉有限公司联系方式 Contact information of Changzhou Shangneng Boiler Co., Ltd., China 联系人:芮亚平 Contact person: Rui Yaping 手机:+8613815029577 Mobile:+8613815029577 邮箱:czjnguolu@163.com Email: czjnguolu@163.com 微信号:13815029577 WeChat ID: 13815029577 工厂地址:中国常州高新区黄河西路225号 Factory address: No. 225 Huanghe West Road, Changzhou High tech Zone, China 开户行:中国工商银行常州钟楼支行 Opening Bank: Industrial and Commercial Bank of China Changzhou Zhonglou Branch 美元帐号:1105020509714031781 USD account: 1105020509714031781 |