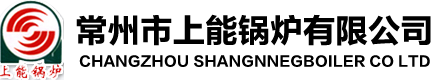

低氮燃气蒸汽锅炉 Low nitrogen gas steam boiler

SZS系列蒸汽锅炉

燃气蒸汽锅炉出口应用于天燃气丰富的中东和西亚国家(如俄罗斯,乌磁别克斯坦,伊郎,伊拉克,沙特阿拉伯,土耳其,印度,巴基斯坦)

Gas and steam boilers are exported to countries in the Middle East and West Asia rich in natural gas (such as Russia, Uzbekistan, Iran, Iraq, Saudi Arabia, Türkiye, India, Pakistan)

SZS系列蒸汽锅炉参数SZS series steam boiler parameters | |

【额定蒸发量】: Rated evaporation capacity: | 4-50t/h |

【额定蒸汽压力】: Rated steam pressure: | 1.25/1.6/2.0/2.5MPa等 1.25/1.6/2.0/2.5MPa, e |

【热效率】: [Thermal efficiency]: | ≥94%(不含节能设备) ≥ 94% (excluding energy-saving equipment) |

【低氮炉型】: Low nitrogen furnace type: | NOx<80mg/m³ |

【超低氮炉型】: Ultra low nitrogen furnace type: | NOx<30mg/m³ |

【应用范围】: [Application scope]: | 工业蒸汽、大型供热站 Industrial steam, large heating stations. |

产品简介 Product Introduction:

SZS型燃气蒸汽锅炉采用汽包纵向布置结构,分为锅炉本体和节能装置两部分。锅炉本体模块化设计,实现了大容量锅炉的整体快速安装,缩短了安装周期,节省了安装成本

The SZS type gas steam boiler adopts a longitudinal arrangement structure of the drum, which is divided into two parts: the boiler body and the energy-saving device. The modular design of the boiler body realizes the overall fast installation of a large capacity boiler, shortens the installation cycle, and saves installation costs.

锅炉内部采用全膜式壁水冷结构,气密性好,减小锅炉主机重量和外形尺寸,缩短启动和停炉时间。

The boiler adopts a full membrane wall water-cooled structure inside, which has good airtightness, reduces the weight and external dimensions of the boiler host, and shortens the start-up and shutdown time.

三回程对流管束结构,合理的烟气流程,较低背压,实现了正压燃烧,尾部布置可分式节能器,降低了排烟温度,避免了本体受热面的低温腐蚀。

The structure of the three return convection tube bundle, reasonable flue gas flow, low back pressure, and positive pressure combustion are achieved. A detachable energy-saving device is arranged at the tail to reduce the exhaust temperature and avoid low-temperature corrosion of the heating surface of the body.

核心优势:Core advantages: | |||||

燃料燃烧充分,热效率高 Fully burned fuel with high thermal efficiency | 大水容积设计 Large water volume design | 优质保温 High quality insulation | 智能化控制 High quality insulation | 低氮排放 Low nitrogen emissions | 运行安全 Operational safety |

大炉膛和对流管束二回程设计,使烟气在炉膛内停留时间加长,可燃气体得到充分燃烧,提高了燃烧效率。锅炉设有节能器,进一步提高热效率。 | 设计中采用了较大的水容积,保留了较大的水位安全范围,使得蒸汽蒸发面大,蒸汽含水率低,保证了蒸汽品质,有效减少了用汽侧负荷骤变对炉内水位的冲击 | 膜式水冷壁外安装轻型保温材料,采用特种复合硅酸盐板覆盖,外挂彩钢板,保温效果好,外观美观。 | 全自动PLC控制,触摸屏高清显示,一键启停,负荷自动调节,各类故障连锁保护。 | 配备低氮燃烧器,采用烟气外循环(FGR)技术 | 锅炉受压本体应力状况良好,锅筒等重要受压元件不直接受高温火焰辐射和冲刷,受压元件伸缩自如,热应力小,实现更高的安全裕度。 |

The design of a large furnace and convection tube bundle with two return paths prolongs the residence time of flue gas in the furnace, allowing for sufficient combustion of combustible gases and improving combustion efficiency. The boiler is equipped with an energy-saving device to further improve thermal efficiency. | A larger water volume was adopted in the design, retaining a larger water level safety range, resulting in a larger steam evaporation surface and lower steam moisture content, ensuring steam quality and effectively reducing the impact of sudden changes in steam load on the water level in the furnace | Light insulation material is installed outside the membrane water-cooled wall, covered with special composite silicate board, and coated with color steel plate. The insulation effect is good and the appearance is beautiful. | Fully automatic PLC control, high-definition touch screen display, one click start stop, automatic load adjustment, and various types of fault chain protection. | Equipped with low nitrogen burners and utilizing flue gas external circulation (FGR) technology | The stress condition of the pressurized body of the boiler is good, and important pressure components such as the drum are not directly affected by high-temperature flame radiation and erosion. The pressure components can stretch and contract freely, with low thermal stress, achieving higher safety margins. |

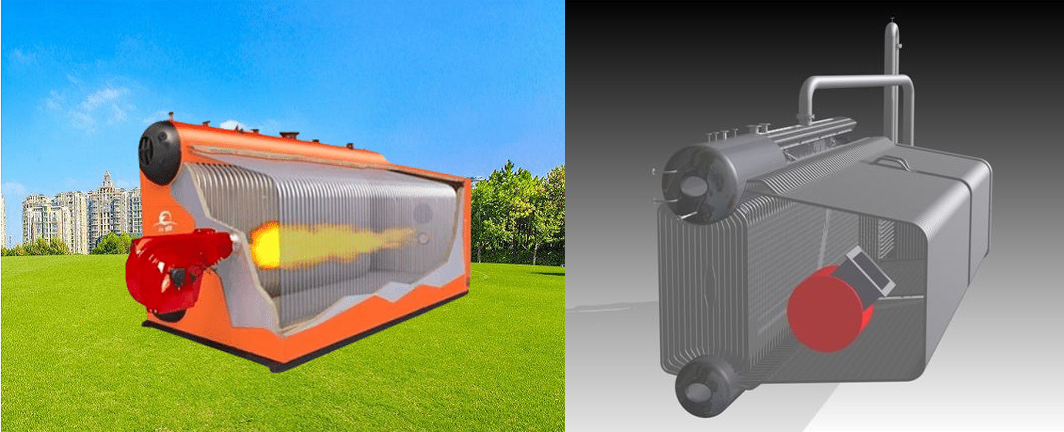

构造与性能 Construction and Performance:

(1)内部结构:

采用上下锅筒纵向布置,上下锅筒间设有对流管束。下锅筒置于锅筒座上,与底座相连,上锅筒通过对流管束支撑在下锅筒上。

(1) Internal structure:

Adopting a longitudinal arrangement of upper and lower drums, there is a convection tube bundle between the upper and lower drums. The lower drum is placed on the drum seat and connected to the base. The upper drum is supported on the lower drum through a convection tube bundle.

(2)水冷壁结构:

锅炉炉膛为膜式水冷壁结构,膜式壁采用专门的膜式壁生产线生产,焊缝波形均匀美观,质量好确保焊接及成形质量。全膜式壁水冷结构,气密性好完全消除烟气泄漏,保证了结构的稳定性,提高炉膛及烟道刚性,提高锅炉炉壁的抗爆能力。

(2) Water cooled wall structure:

The boiler furnace adopts a membrane water-cooled wall structure, and the membrane wall is produced by a specialized membrane wall production line. The weld waveform is uniform and beautiful, and the quality is good to ensure the welding and forming quality. The full membrane wall water-cooled structure has good airtightness and completely eliminates smoke leakage, ensuring the stability of the structure, improving the rigidity of the furnace and flue, and enhancing the blast resistance of the boiler wall.

(3)烟气系统:

锅炉采用了大炉膛和对流管束二回程设计,使烟气在炉膛内停留时间加长,可燃气体得到充分燃烧,提高了燃烧效率。炉膛与对流管束通过水冷壁分开。高温烟气首先在炉膛内与水冷壁进行高效换热,避免了直接高温烟气直接冲刷锅筒,延长了锅炉的使用寿命;烟气在经后烟箱进入二回程对流管束,进一步散热;流经对流管束后,烟气离开锅炉本体,通过连接烟道进入尾部受热面(节能器等热回收装置),再进入烟囱排入大气。

(3) Smoke system:

The boiler adopts a large furnace and convection tube bundle two return design, which prolongs the residence time of flue gas in the furnace, fully combusts combustible gases, and improves combustion efficiency. The furnace and convection tube bundle are separated by a water-cooled wall. High temperature flue gas first efficiently exchanges heat with the water-cooled wall in the furnace, avoiding direct flushing of the boiler drum by high temperature flue gas and prolonging the service life of the boiler; The smoke enters the secondary convection tube bundle through the rear smoke box, further dissipating heat; After passing through the convection tube bundle, the flue gas leaves the boiler body and enters the tail heating surface (such as the energy-saving device) through the connecting flue, and then enters the chimney to be discharged into the atmosphere.

(4)配件 Accessories

节能器 Energy saving device | 压力表 Pressure gauge | 超压保护装置 Overpressure protection device | 水位计 Water level gauge | 布水器 Water dispenser | 烟气冷凝水收集排放 Collection and discharge of flue gas condensate water | 锅筒配件 Drum accessories |

分体式安装,可依现场实际情况灵活安装。采用优化设计的翅片管换热器,翅化比大,翅化效率高,烟气流阻小。 | 大口径表盘、指针显示、高精度压力表;配备专用压力表缓冲管。 | 远传压力报警、机械式压力开关报警、弹簧全启式安全阀三重超压保护装置,确保锅炉在额定压力以内工作。 | 锅炉两侧,通过平衡桶连接水位计,板式、双色、浮筒等多类水位计可选,水位观察直观、检测稳定、控制灵敏 | 锅炉给水入口设置专用布水器,给水经布水器后分散均匀地进入锅炉,避免了给水时的局部温度骤降。 | 采用合理的烟道结构,燃气燃烧产生的冷凝水迅速汇集,在前后烟箱排出,极大限度减小了冷凝水对锅炉的腐蚀 | 人孔、手孔等检查孔设置齐全,位置合理,维护检修方便。 |

Split installation, flexible installation according to actual on-site conditions. The finned tube heat exchanger with optimized design has a high finning ratio, high finning efficiency, and low flue gas flow resistance. | Large caliber dial, pointer display, high-precision pressure gauge; Equipped with dedicated pressure gauge buffer tube | The triple overpressure protection device includes remote pressure alarm, mechanical pressure switch alarm, and spring fully open safety valve to ensure that the boiler operates within the rated pressure. | On both sides of the boiler, a water level gauge is connected through a balance bucket. Multiple types of water level gauges, such as plate, dual color, and float, are available. The water level observation is intuitive, the detection is stable, and the control is sensitive | A dedicated water distributor is installed at the inlet of the boiler feed water, which disperses and evenly enters the boiler after passing through the distributor, avoiding local temperature drops during feed water. | By adopting a reasonable flue structure, the condensed water generated by gas combustion quickly collects and is discharged from the front and rear smoke boxes, greatly reducing the corrosion of condensed water on the boiler | Manholes, handholes, and other inspection holes are fully installed, reasonably positioned, and easy to maintain and repair. |

(5)外观 Appearance

立体雕塑型外观,在传统外观工艺基础上,采用加固筋的压花钢板立体包装,外观时尚,结构牢固,稳重大气。

The three-dimensional sculptural appearance adopts reinforced embossed steel plate three-dimensional packaging on the basis of traditional appearance technology, with a fashionable appearance, firm structure, and stable atmosphere.

(6)系统图 System diagram:

SZS系列燃油(气)低氮蒸汽锅炉主要技术参数 Main technical parameters of SZS series fuel (gas) low nitrogen steam boilers

项目 project | 型号 model | SZS4 | SZS6 | SZS10 | SZS15 | SZS20 | SZS25 | SZS30 | SZS35 | SZS40 | SZS50 |

额定蒸发量 Rated evaporation capacity | t/h | 4 | 6 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 |

额定压力 Rated pressure | MPa | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 | 1.0/1.25/1.6 /2.0/2.5 |

蒸汽温度 Steam temperature | ℃ | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 | 184/194/204 /215/224 |

锅炉热效率 Boiler thermal efficiency | % | >94 | >94 | >94 | >94 | >94 | >94 | >94 | >94 | >94 | >94 |

适应燃料 Adapt to fuel | 轻柴油、天然气、焦炉煤气、城市煤气 Light diesel, natural gas, coke oven gas, urban gas | ||||||||||

最大件外形长度 Maximum external length of the component | mm | 6000 | 6450 | 7590 | 8550 | 8400 | 9200 | 10500 | 11470 | 11470 | 12000 |

最大件外形宽度 Maximum external width of the component | mm | 2400 | 3350 | 3660 | 3550 | 3960 | 3960 | 4400 | 4400 | 4400 | 3250 |

最大件外形高度 Maximum external height of the component | mm | 3400 | 3460 | 3680 | 3490 | 3900 | 3900 | 4230 | 4230 | 4230 | 3890 |

最大件运输重量 Maximum transportation weight | t | 25 | 33 | 36 | 40 | 48 | 52 | 57 | 62 | 67 | 72 |

本产品如因技术改进所进行数据的变化,恕不预告,并以现时图纸为准 。Any changes to the data of this product due to technical improvements are subject to no prior notice, and the current drawings shall prevail.

| 中国常州市上能锅炉有限公司联系方式 Contact information of Changzhou Shangneng Boiler Co., Ltd., China 联系人:芮亚平 Contact person: Rui Yaping 手机:+8613815029577 Mobile:+8613815029577 邮箱:czjnguolu@163.com Email: czjnguolu@163.com 微信号:13815029577 WeChat ID: 13815029577 工厂地址:中国常州高新区黄河西路225号 Factory address: No. 225 Huanghe West Road, Changzhou High tech Zone, China 开户行:中国工商银行常州钟楼支行 Opening Bank: Industrial and Commercial Bank of China Changzhou Zhonglou Branch 美元帐号:1105020509714031781 USD account: 1105020509714031781 |